Hull

A jackup hull is distinct due to its shape, which is designed to accommodate the legs and increase the deck space. Jackup hull is not designed for navigation in rough weather or high speeds due to its low freeboard and box shape.

- Engine Room: Similar to other vessels, the engine room houses all the necessary machinery. However, it also includes additional equipment to support the jacking system.

- Accommodation Block: This area is designed to house the crew required to operate the vessel and any additional project personnel. Typically, a jackup accommodates around 25 marine crew members, but can hold many more, with some having a capacity over 300 people.

- Bridge: If the jackup is self-propelled, it will include a standard navigation bridge, just like any other seaworthy vessel.

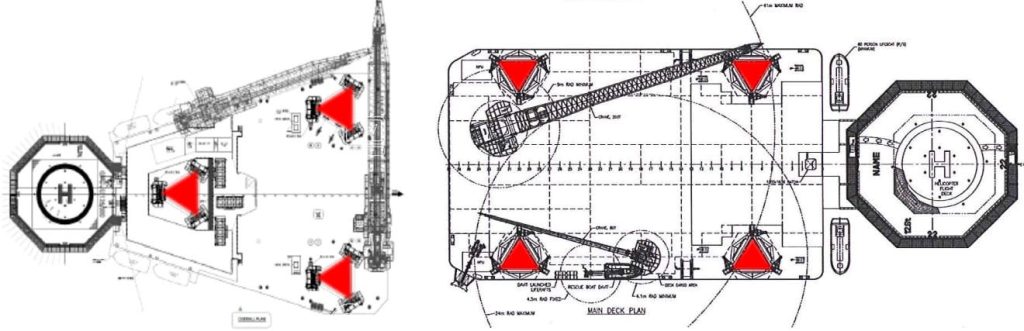

- Cranes: At least one large crane can be found on the deck, possibly more to ensure coverage of all sides of the vessel. Cranes are essential to jackups as they are the only means to load cargo from Supply Vessels (PSVs) and carry out construction tasks.

- Main Deck: A larger hull provides more cargo space, a bigger deck surface, and larger tanks for better autonomy. However, a bigger hull also means more weight and a higher load on the jacking system, which is why the size of the jackup and the power of the jacking system are determined by its intended use.

The strength of the hull is important, due to the high loads imposed on it by the legs and jacking systems (or by drilling structures such as cantilevers on the drilling rigs). The platform structure is determined through many complicated strength calculations, considering all modes of operation and survival. The structure may contain heavy high strength steels around the leg wells, leg guides, and jacking system connection.

Legs

Jackups are easily identifiable due to their legs. Leg towers are attached to the hull and holding the legs in place, as well as rails that guide and secure these legs.

In the elevated condition the legs are subject to many large forces. The weight of the hull, with accommodation and machinery, in addition to hookloads (cargo), etc., pushes down on the legs through the jacking or lock-off systems. In addition, they are subject to lateral forces caused by wind, waves, current and sometimes supply boats colliding with them. In severe weather and sea conditions these forces can be very large.

The legs serve two main purposes:

- to lift the vessel above the sea surface

- to withstand the forces of the environment, such as wind and waves.

There are two types of the legs:

- cylindrical (tubular)

- trussed (lattice).

When the jack-up vessel is afloat, legs are pulled up and sometimes extend well over 100 meters above the sea. However, legs can affect the vessels’ stability in floating condition due to their weight, high centre of gravity, and the large surface area exposed to the wind.

The forces on the legs themselves are very large due to the roll and pitch of the vessel.

These factors need to be considered when calculating the vessel’s afloat stability.

For this reason, some jack-up vessels have procedures in place to lower the legs in case of bad weather. Lowering the legs helps to lower the centre of gravity and improve the vessel’s stability.

However, it’s important to note that jack-up vessels are not primarily designed to stay afloat or to travel long distances. They are not meant to be moved during bad weather, either. The main purpose of a jack-up is to provide a stable platform above the water surface, rather than to navigate the seas.

The legs are lowered to the seafloor, causing the hull to rise out of the water until it reaches the desired height, known as the air gap. Each leg can move independently to adjust for an uneven seabed or uneven penetration into the seabed, while maintaining the hull levelled.

3-leg and 4-leg jackups

Jackup barges are commonly equipped with three or four legs. The three-legged barges are typically more affordable and straightforward to build. However, they may not offer the same level of stability as their four-legged counterparts.

Four-legged barges excel in their superior stability in elevated condition. They also transition more quickly from floating to elevated status due to a quicker “preload” process, which we’ll delve into later. Furthermore, four-legged barges have the added benefit of a larger hull size, increased deck area, and higher weight capacity, allowing them to carry more cargo when raised.

Typically, these four-legged barges are larger, providing additional deck and cargo space. They often have more fuel and water storage, adding to their authonomy. While most are box-shaped, there are some ship-shaped models.

Despite these benefits, four-legged barges do come with some drawbacks. They have a larger surface area that is impacted by environmental conditions and a deeper draft due to their increased displacement. Additionally, they are more expensive to construct and operate.

On the other hand, three-legged barges, typically triangle shaped, are less costly due to their simpler design, smaller size, and reduced machinery requirements. Cost savings begin at the construction stage where one less leg and associated lifting mechanism are needed. This also results in a lower power requirement, allowing for the installation of a more economical generators and jacking system.

There is also an important factor of weight distribution. The distribution of the weight over each leg is easily determined on three legged vessels. With four leg units, the preloading procedures may be quite different and the distribution of platform weight over each leg may have to be watched more closely (remember 4 legged tables with slightly uneven leg length).

In the long term, these savings continue as less fuel and jacking grease are consumed, and there is less machinery to maintain. Smaller barges may also reduce costs further by requiring fewer personnel. Overall, the choice between three and four-legged barges is a balance between cost and capability.