Mobile Offshore Units (MOU)

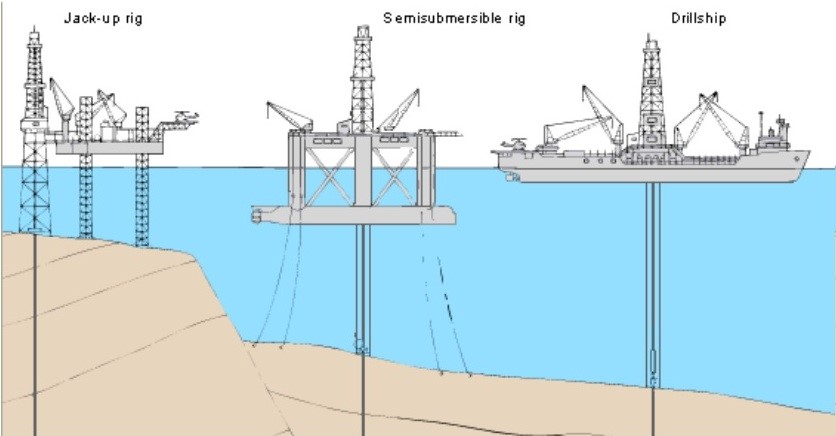

Mobile offshore units used for oil and gas exploitation can be broadly classified into three main categories:

- Jack-up

- Semi-submersible

- Drill ship

Each vessel type serves its own purpose, with distinct advantages and limitations. The key differentiating factor is the working depth. Jack-up vessels can operate in relatively shallow waters compared to other types of vessels, with their leg length serving as the limiting factor. Typically, the maximum depth for these vessels does not exceed 120m. However, there is a specialized class of jack-up vessels known as premium or ultra-premium jack-ups that can operate in water depths ranging from 150 to 190 meters. Notable among these is the Maersk MSC C170-150 MC, which can operate in waters as deep as approximately 168m (550 feet).

Despite the limitations posed by the length of their legs, jack-up vessels are the most cost-effective to build and operate. This gives them a significant advantage in oil-rich regions like the Arabian Gulf countries, where the average depth of 50m and even maximum depth of 90 m is within the operating limitations of a jack-up vessel.

Jackups

Jackups are specialized structures, categotised as Mobile Offshore Units (MOU), designed for operations in shallow waters (Less than 100 m). They have the ability to move as a vessel, but also to root their legs on the sea floor, providing a stable platform for for a variety of jobs, including drilling, construction, and maintenance. Notably, each leg is individually adjustable to different depths, which allows for operations on an uneven seabed.

Within the category of jackups, a distinction exists between non-propelled (e.g. drilling rigs) and self-propelled jackup vessels.

Our focus here will be primarily on self-propelled jackup vessels.

In their waterborne state, these units operate in “afloat condition”. This allows them to move usung their own propulsion and move between different worksites.

Moreover, the market for these jack-up rigs is growing (estimated value of USD 15.41 billion expected by 2028). This growth is driven in part by the increasing demand for oil and gas extraction from offshore fields, as well as the cost-effectiveness of drilling offshore.

Semi-submersibles

Semi-submersibles are especially designed for deepwater operation and harsh environments. Unit is supported by large, hollow, columns connected to pontoons. The pontoons provide buoyancy and can be flooded by ballast to partially submerge to a desired draught, hence the term “semi-submersible”.

The main advantage of this design is its stability, which is crucial for precision tasks like drilling, where movement of the platform can cause serious problems.

Semi-submersibles can be either self-propelled or towed. Once on site, they are anchored to the seafloor using a system of mooring lines. In recent years, semi-submersibles have also been fitted with DP systems

While semi-submersible platforms are capable of operating in deep water (300 m), they are not typically designed for ultra-deep water operations. For these operations, drillships are often used.

Drill ships

It is a purpose-built vessel, to conduct offshore drilling at ultra deep water, sometimes up to 3000 m deep.

Advantages of a drillship are its mobility and deepwater capabilities, while disatvantages are sensitivity to weather and the cost of chartering such vessel.