Jack-up barges, due to their diverse applications, predominantly feature two design types for their legs:

CYLINDRICAL (tubular) and TRUSSED (lattice).

The cylindrical leg design is characterized by its simplicity – such legs are hollow steel tubes. This is a more traditional design, commonly seen on jack-ups operating in shallow waters. Its primary advantage lies in the small diameter of the legs, which occupy less usable space on the main deck, leaving more room for deck cargo.

Despite being an older design, it remains a popular choice for jack-ups used in shallow waters. They are simpler to fabricate and maintain compared to lattice legs.

However, they offer less stability than lattice legs and cannot as effectively adapt to water-induced stresses.

Conversely, the lattice (or trussed) leg design boasts a more robust construction (tubular steel sections), facilitating the construction of larger units with longer legs (stronger and lighter). This design allows the jack-up to reach greater depths and bear more weight on deck.

However, the more intricate design and larger diameter come with a higher price tag and consume more usable deck space.

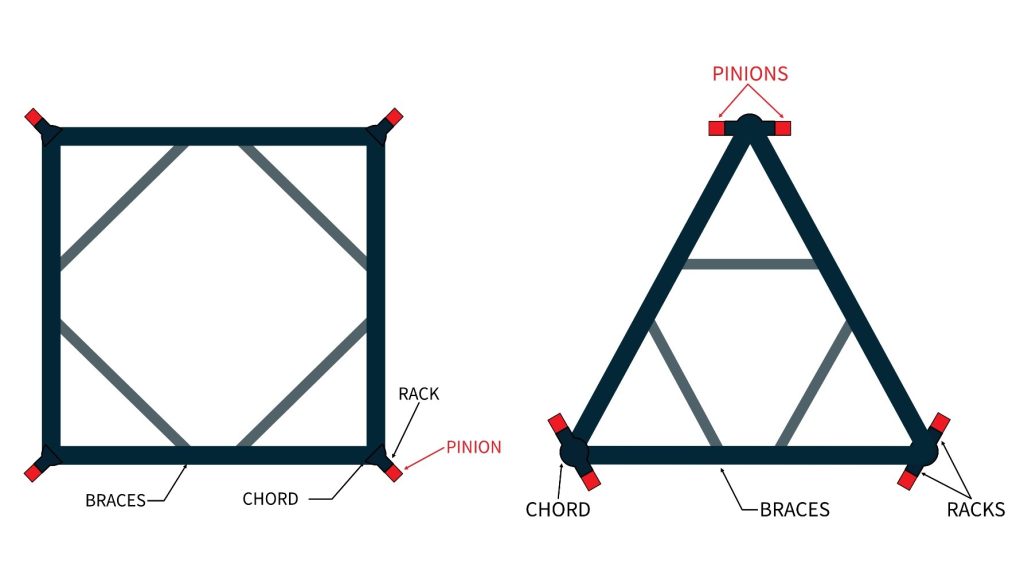

Subdivision of lattice legs occurs into 3-chord and 4-chord designs.

Lattice legs may consist of 3 or 4 vertical construction elements, known as chords, which are the primary construction elements linked by smaller horizontal elements called braces.

These chords also support a rack, enabling the leg’s vertical movement.

A 3-chord leg holds two racks, while a 4-chord leg holds one.

The 4-chord design provides superior stability when the hull is elevated and can support more weight. However, it occupies a larger surface area on the main deck.

Recent design developments are directed at minimising the wave, current and wind forces on truss legs, by using fairer shapes for the truss members (in particular the chords), and by improving the way the legs are connected to the hull while elevated (guides, jacking systems, lock-off systems).