The footings of a jack-up barge (also known as spud cans or pads), are steel supports located at the base of each leg. Spud cans interface directly with the seabed. When the legs are extended to the sea floor, the spud cans act as temporary foundations for the structure, providing both vertical and horizontal support, as well as moment restraint against wind and wave loadings.

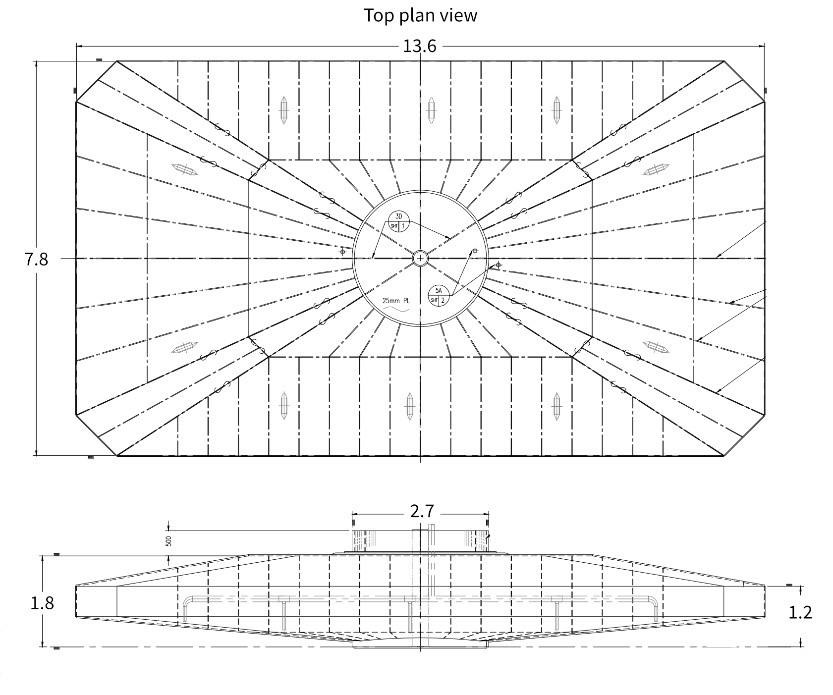

Footings have been designed and built in many different shapes and sizes.

In general, their purpose is to increase the bearing area at the bottom of the leg.

Typical bearing pressures during storms are 28 t/m2 – 43 t/m2 for the larger jack-ups, but sometimes as low as 14 t/m2 for small units, and as higher as 145 t/m2 for rigs specially designed for hard bottom.

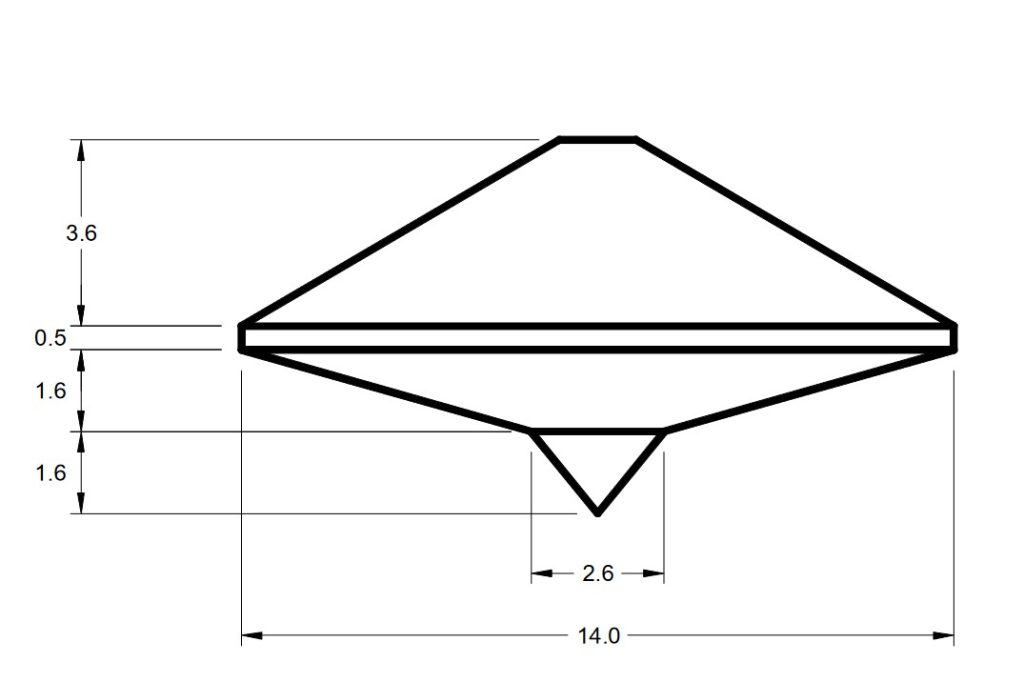

Footings typically have sloped tops and bottoms, a design seen in the accompanying illustration. The sloped top assists in removing accumulated mud when retracting the leg, while the sloped bottom can aid penetration into harder seabeds.

Unless specific requirements are imposed by the rig owner, designers will select a compromise footing design to cover a wide range of requirements such as:

- Provide a bearing area that is large enough to operate in relatively soft soil, limiting excessive penetration into the seafloor.

- Incorporate a sharp cone or cookie cutter to provide some minimal penetration in hard soils for lateral resistance.

- Capability to be retracted in the hull far enough to allow easy dry transport of the rig and limit draft afloat.

Dimensions of the spud cans vary, but drilling rigs usually have footings arround 14 m in diameter, with conical shape to increase horizontal restraint at sites with small penetration.

Self propelled jackups utilize even larger spudcans, which are square shaped, to distribute weight around larger surface thus reducing the penetration into the seabed.

By increasing the size of the footings, the pressure on the load-bearing area is reduced, thereby minimizing the leg’s penetration into the ground.

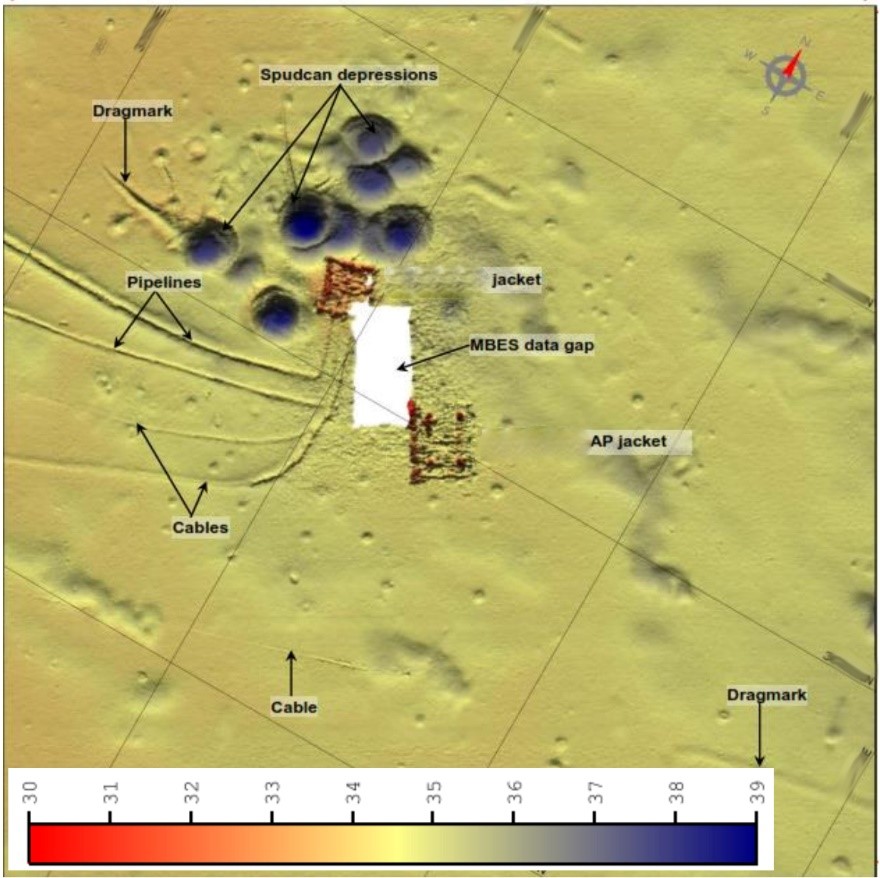

One of the challenges with jack-up barges is the footprints they leave in the seabed due to the penetration of the spud cans.

This can be problematic for subsequent jack-ups visiting the same location, as positioning a footing over the depressions can lead to uneven pressure distribution on the spud cans.

To avoid such complications, a thorough seabed survey should be conducted before deploying the legs at any location. This survey provides comprehensive information about the seabed, aiding in making informed decisions regarding the positioning of the jack-up and the placement of its legs.