Backlash in engineering is the distance between the paired gear teeth. It is the amount of ‘play’ or ‘give’ between two mechanical parts that engage each other. Every such part (gear, thread, etc.) has some backlash by design, because without it the two parts would bind up and wouldn’t be able to move. The problem is when backlash increases above the allowed tolerance.

That happens due to the wear of the components (rack and pinions) during jacking operations, when pinions are loaded the most (when turning, while lifting the hull). Pinions are also affected while the hull is elevated, if lock-off systems are not installed and the whole weight is held on pinions.

Weight is pushing downwards, while weather elements are swinging the hull sideways, causing the pinion-rack-interface to wear out. Pinions will be affected more than the rack, because rack is usually built of stronger steel than the pinion teeth, to allow their replacement.

The manufacturer will provide the factory settings of the backlash, as well as the wear limits. The backlash of the pinions is checked when possible (usually in shipyard), and results are recorded for tracking purposes.

If the backlash starts to increase, it is time to ask ourselves “why”. It might be due to the various factors, depending on the age of the jackup, number of jacking operations, load distribution, or anything that is loading the pinions. Age and history of the barge moves have to be analysed in order to find a cause of backlash increase.

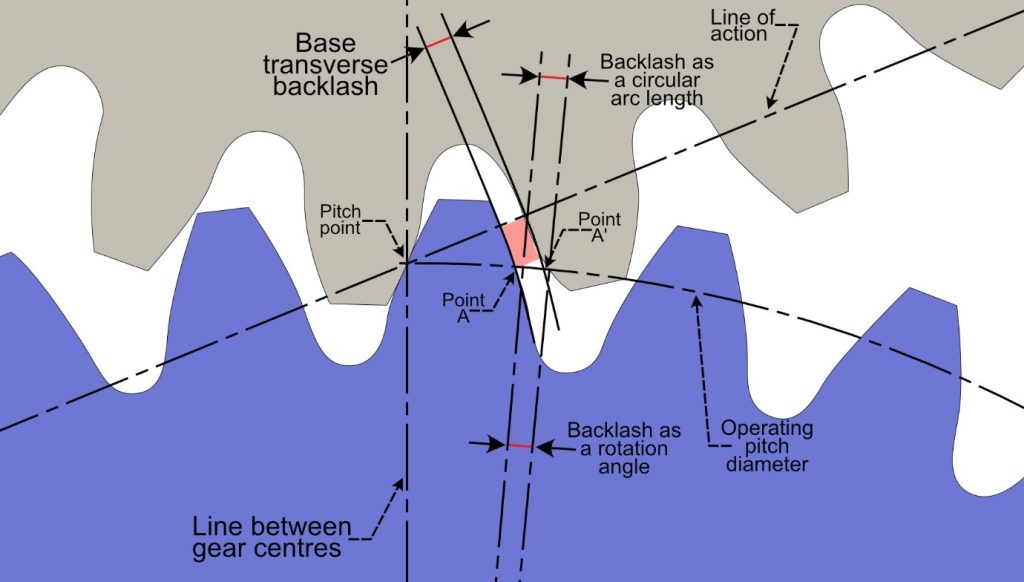

It is important not to disregard the backlash of a jacking system, because it can cause damage to the whole system, even the rack failure. It is measured at the PITCH POINT of the pinion tooth, as shown on the illustration.