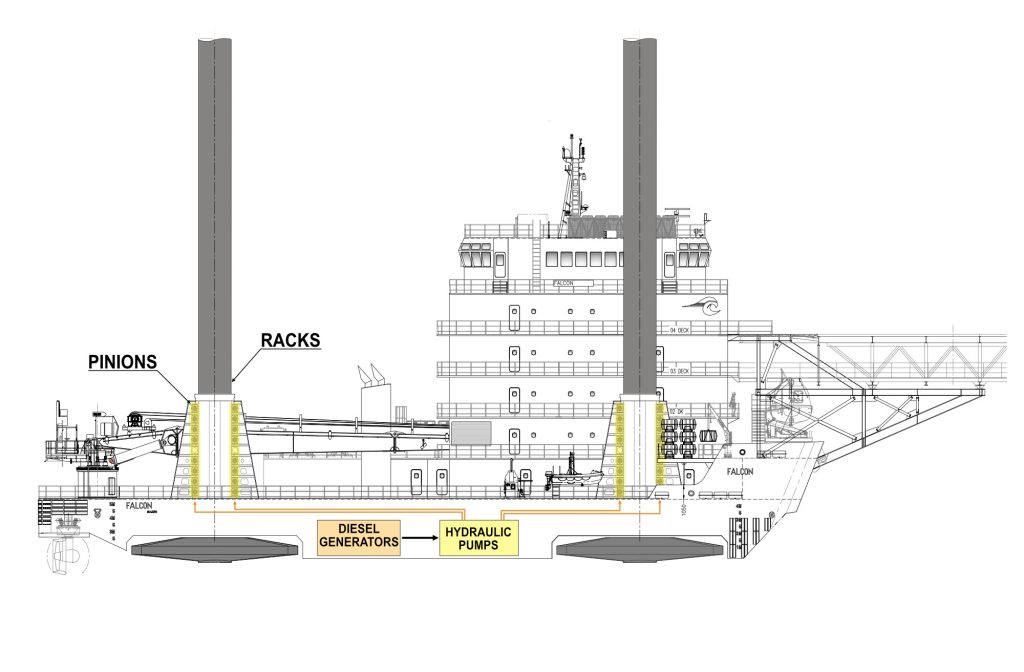

Jacking system load limits

Every jacking system has its limitations in terms of weight. Those limitations are not the same for every operation mode. Usually you will find three types of limitations in the operation manual of the barge: Maximum JACKING rating: It refers to the maximum load that the jacking system can handle. This rating determines the rig’s […]