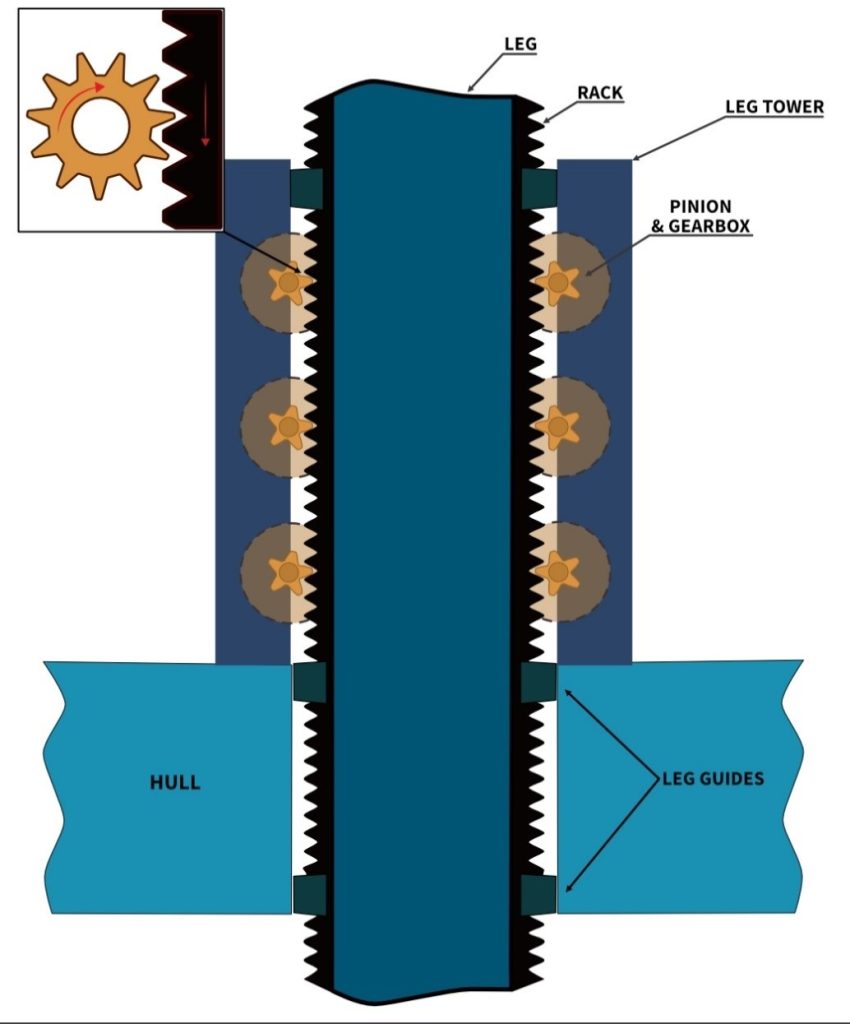

The rack and pinion system is a more advanced and widely-used mechanism in today’s jack-up rigs.

The system consists of a pinion attached to the gearbox, which is driven by an electric or hydraulic motor. The pinion rotates and meshes with the RACK (attached to the leg), lifting the leg up or lifting the hull up.

The advantage of this system is that it allows for continuous lifting and lowering the hull. The leg is held in line by the upper and lower guides, which ensure the legs move only in vertical directions, and maintain a distance between the rack and the pinions.

The weight of the hull is held by the pinions, so their capacity will be the limiting factor of the jacking system.

Each leg is fitted with several pinions, each of them driven by its own gearbox and motor (electric or hydraulic).

Motors have a built-in, fail-safe brake, that engages automatically when current is interrupted (electric systems) or when pressure drops below a certain value (hydraulic systems). That way, brakes can safely hold the hull even in case of a blackout.

Jacking speed and capacity (weight) will be determined by power and quantity of the motors installed on each leg.

On the photo, you can see that 9 motors are installed on each side of the leg (18 motors in total). That many powerful motors give it the ability to jack-up with cargo at speed of 1.2 m/min.

While the barge is in elevated condition, the hull is normally supported by the brake system, unless the “lock off devices” are installed.

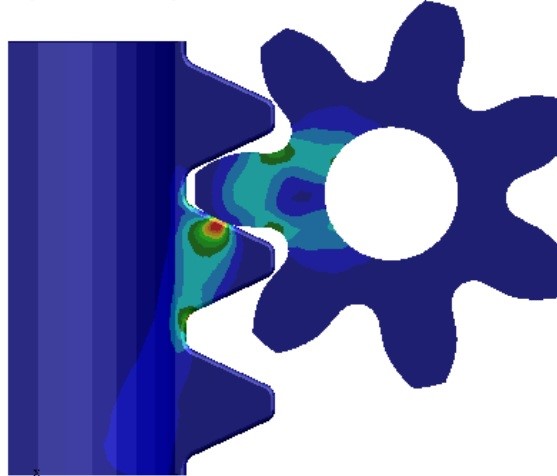

The rack and pinions of a jack-up sustain a tremendous load, especially when the weight is not equally distributed to them.

The point where the rack touches the pinion is called pinion-rack-interface. It takes most of the pressure, as we can see on the image.

The jacking system has to be able to equally distribute the torque between all motors and pinions, otherwise one pinion might be overloaded and damaged.